Today, the printing industry is fully engaged in automated equipment and technology. The impressive pace of its development, as well as the high level of competition in the market of services require the introduction and use of new means of accounting for materials. The actuality of this research is based on increasing demands to quality and speed of calculation processes, and also by the fact that nowadays, the integration of all stages of manufacturing printing products, including the accounting, in automatized system is the most appropriate course of development of the production.

The questions, concerning the automatization of the printing process are actively studied in the last decades. These questions were paid attention to by I. N. Mayatskaya, V. V. Gogolev, O. A. Baronina, V. V. Kovaleva, V. N. Drozdov and others. In particular, the questions of automation of accounting in the printing industry were touched upon by such scientists as S. A. Shcherbakov, V. V. Gogolev

The direction of automatization of accounting of printing enterprises are developing quite rapidly. On the market there are online and offline calculators, specified to count the prices as for separate operations, materials as for complete technological process of manufacturing of a product.

This work aims to modernize and automate the process of calculating the printing materials while operating to bond the blocks with wire, through the development of specialized software based on the programming environment of Visual Basic.

So, in organizing the process of work, printing companies, printing houses and printing shops, certain problems arise faced by executives and managers of industrial and commercial services. Among them are the following [1]:

- the low speed of calculation of orders;

- the use of simplified schemes and algorithms of calculations;

- the springing up of errors in the description of technological process of manufacturing printed products;

- the high labor content of the accounting process in manufacturing

The above-mentioned problems can be solved by applying the specialized tools in the form of calculation modules at the printing enterprises.

The developed software serves to counting of the printing wire while sewing blocks by ways: either saddle stitch or side stitch; and can also be used in the further calculation of the material cost.

In the design process, the calculating module was put forward the following specificational and functional demands:

- the ability to work in operating systems of the Windows family

- the installation of database management system MS Access

- the availability of choice of technology of sewing

- the ability to obtain calculated values in linear metres and kilograms

- easy operation

The realization of the above demands was carried out using the model of object–oriented programming in the Visual Basic environment.

In the software module, to facilitate the calculation process, the hierarchical database of the printing paper of the world’s largest suppliers is integrated, in particular, Arctic Paper (Poland), Stora Enso (Sweden–Finland), Mondi SCP, Slovakia), UPM (Germany), Sappi (South Africa), Artone Paper (South Korea), Hansol Paper (South Korea) Burgo (Italy), APP (China) and OJI Paper (Japan). Database is created using Microsoft Access. The integration is realized via the ORM technology that connects the database with the concepts of object–oriented programming languages.

The disadvantage of the chosen method of creating software is limiting the use of the product by the operating systems of Windows and MAC OS only.

The calculation of the amount of wires needed for the producting the circulation is conducted on the basis of information about the product being entered through the main window of the developed program. Initial data for calculation is the way of sewing, format, circulation, the volume of edition, presence and characteristics of additional elements, and characteristics of the paper used.

The basis for the algorithm is the method of calculating the amount of printing wire, described by Z. V. MAIK in the publication “Technology of post press processes” [2]. Algorithm has the following form:

- assigning data types to variables;

- prohibition of entering unnecessary marks;

- checking the existence of input data;

- database connection paper;

- building queries that fetch data from the database;

- assigning data to variables;

- the defining of the two highest multipliers;

- the calculating of the height of the block;

- calculating of the thickness of the block;

- the defining of a method of sewing;

- the determination of the presence of additional elements;

- calculating of the thickness of drilled block

- calculating of the length of the staple back;

- the calculating of the number of staples for sewing one block;

- the calculating of the quantity of wire in meters;

- the determination of diameter of wire;

- the determination of the weight of 1000 metres of the wire;

- the calculating of weight of wire

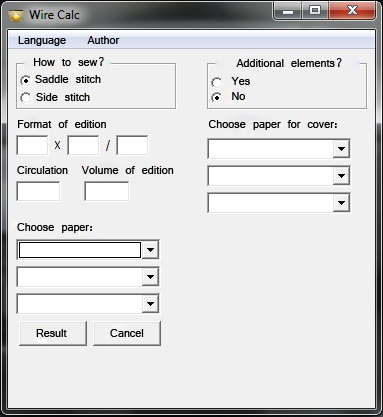

The main window of the calculation module of the printing wire in a standby has the look depicted in Fig. 1

Fig. 1. The main window of the calculation module of the printing wire in a standby.

Fig. 1. The main window of the calculation module of the printing wire in a standby.

The main window contains the switcher of the method of sewing edition as well as requests for data input to calculate which include: format of edition, volume of edition in the printed sheets. The presence or absence of additional elements is determined by the switch.

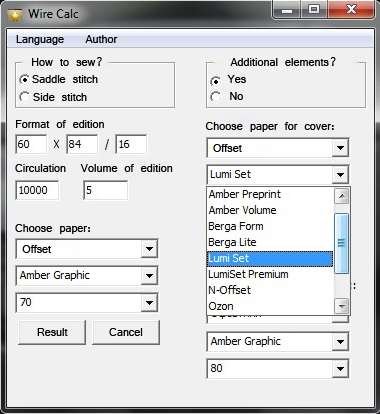

Since the number of printing wire depends on the thickness of the printed paper, the program has a hierarchical database containing the main characteristics of printed papers (Fig. 2).

Fig. 2. The look of the window of the calculation module of the printing wire at the stage of filling

Fig. 2. The look of the window of the calculation module of the printing wire at the stage of filling

When all the fields are filled in, click the button “Result”, then the window shows the sought value.

So, the advantages of using the software for calculating the amount of materials used in the manufacture of editions, become apparent. The software allows you to increase the speed of calculation processes, to reduce the probability of calculation errors and also to reduce the labor content of the process of accounting. Thus, the developed software meets all requirements and can find practical application not only in the educational purposes, but also in a wide range of professionals in the print industry.

References

- Иванов П. К. Системы управления современным полиграфическим предприятием: автореф. дис. …канд. техн. наук: 05.13.06 – М., 2009. – 182 с.

- Маїк В. З. Технологія брошурувально–палітурних процесів [Текст]: підручн. для вузів / В. З. Маїк. – Львов.: НВЕД УАД, 2011. – 488 с.