In modern economic conditions the optimization of processes in the company occupies one of the most important requirements in the development and prosperity of the organization. The TQM issue is widely used nowadays but it also had relevance in the middle of the 20th century.

According to the analysis of theoretical sources where the aspects of basic principles of TQM are represent, the entire management system works effectively if the organization is viewed as a whole and unified system[1-3]. In this case, to increase efficiency and optimize processes it is necessary to observe the basic principles of TQM, which are following:

- Focus on the customer’s organization;

- Leadership;

- Involvement of employees;

- Process approach;

- Constant improvement;

- Approach to decision-making based on facts;

- Communication with suppliers;

- Minimizing losses associated with poor quality work.

- Focus on the customer’s organization.

The organization is entirely dependent on their customers and therefore obliged to understand the needs of the customer and comply with the requirements and strive to exceed their expectations. Even a quality system that meets the minimum requirements should be focused primarily on the requirements of the consumer. A systematic approach to customer orientation begins with the collection and analysis of customer complaints and claims.

2. Leadership.

Leaders of the organization set common goals and focus areas, as well as ways to achieve the goals. They must create an environment in the organization where the employees will be involved in the process of achieving their goals.

3. Involvement of employees.

The entire staff – from top management to workers – must be involved in quality control activities. The staff is viewed as the greatest wealth of the organization. The top management is to create the conditions where the employees skills are discovered and effectively used [ 4].

4. Process approach.

For best results, relevant resources and activities in which they are involved, should be considered as a process.

Process model of the enterprise consists of a set of business processes, the participants of which are the structural units of an organizational structure.

5. Constant improvement.

In this direction, the organization should both keep track of emerging problems and take the necessary corrective and preventive action to avoid the existing problems in future.

Goals and objectives are based on an assessment of the degree of customer satisfaction (obtained during feedback) and performance indicators of the organization. The improvement should be accompanied by the participation of leadership in this process, as well as providing all the resources which are necessary to achieve its goals.

6. Fact based approach.

Effective decisions are based only on reliable data. The sources of such data may be the results of internal quality system audits, corrective and preventive actions, complaints and wishes of customers, etc.

Also, information can be based on the analysis of ideas and proposals from members of the organization and to improve the productivity, cost reduction, etc.

7. Communication with suppliers.

Since the organization is closely linked with its suppliers, it is appropriate to establish a mutually beneficial relationship with them in order to further empowerment activities. At this stage some documented procedures must be observed at all stages of supplier collaboration.

8. Minimizing losses.

Minimizing losses associated with poor quality work provides the ability to offer products at a lower price. Standard work is the absence of defects, or – “do it right at the first time.”

The article focuses on the seventh principle of “taking decisions on facts.” The abovementioned principle was described in many scientific studies including different directions and ideas. For example L.Glukhova suggested personal approach and the Agent model providing both innovative and effective performance of organization [4, 5,6].

Some other studies consider the possibility of its implementation in financial and pedagogical directions [ 7,8].

According to their ideas the improvement in quality of products and processes requires both cost for staff training and rigorous work of plant personnel to get knowledge and skills for identifying the causes of defects (deviations from the documentation), and providing activities remove them.

To achieve this goal knowledge of financial statistics to develop methods for the analysis and processing of data, identifying the root causes of defects and skills to develop measures to deal them at the lowest cost are required.

This article also discusses the principle of «making a decision on the basis of the collection these facts». To implement this principle in practice some time-consuming methods of measuring and recording the duration of action are used .To follow the idea of this principle it is necessary to determine the time and fix it.

The authors consider the implementation of this principle on the example of «Valeo» company located in Samara region.

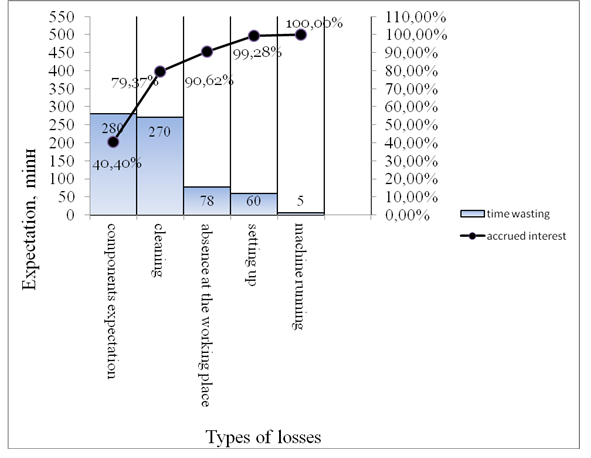

Figure 1 – Diagram of Pareto

On the basis of this chart (Figure 1) shows that the greatest number of losses is applied to items such as the expectation of completing and cleaning.

The most visible and important cause of loss of time in the company is the first situation. In the body shop, auto components are in one location, and workers are in the other. In order to solve this problem some scientists suggest to implement one of the tools of lean production, namely Spaghetti diagram [1.2,7,8].

To compile the Spaghetti diagram it is necessary to put on a clean sheet layout area, in the area where the employee is moved in step, and then apply without tearing his moves on the sheet. The observation is recommended during an hour and 20 working operation cycles at least.

To conclude it is necessary to mention that for improving the performance of organization management should do it by reducing the losses on the movement, thereby freeing up useful time for employees and facilitating their work. Releasing time employee can take more work, adding value process, having balancing operations and thereby reduce costs in the system. The second situation which is relevant today due to business leaders want to reduce operating costs of the subsidiary. It turns out that employees are doing both their basic and auxiliary work for the same salary. To resolve this issue and free up staff time, it is proposed to hire a third-party company outsourcing or create your own maintenance department. When you create a service department to solve the problem, it increases the time to perform basic tasks. Also it allows you to give more jobs, increasing employment levels and reducing unemployment problem.

References

- Juran J.M., Godfrey A.B. Juran’s Quality Handbook PDF. McGraw-Hill. New-York, 1998.

- Taguchi G. Experimental Designs. 3-d ed. Vols. 1,2. Tokyo: Maruzen Publishing Company, 1976.

- Kano Noriaki (1984-04-01). «Attractive quality and must-be quality». The Journal of the Japanese Society for Quality Control: 39-48.

- L. Glukhova Methodological bases of quality management of information specialists training // Bulletin of Samara Scientific Center of the Russian Academy of Sciences. 2006 p.115

- L. Glukhova Methodology for the development of business processes and business planning in industries // Herald PVGUS, number 2010. 13, pp 14-21

- L. Glukhova, AA Sherstobitova Simulation of the financial mechanism of management of development of enterprises // Vector Science TSU, 2015. № 1 (20). S.25-28.

- Akhmadzhanow S, Sherstobitova A, S Gudkova ways to enhance the competitiveness of enterprises. I Practika sovremennoy Theory of Science 2016 N 4 (10) P 76

- L. Glukhova, Syrotyuk YSD-related parameters and the definition of indicators of quality of the content in-house training // Vector Science TSU, 2014, № 4 (19), s.36-38.

View this article in Russian

View this article in Russian