One of the main tasks of modern production is to ensure scientific and technological growth. One of the main conditions for its implementation is the continuous improvement of technology, technological equipment, tools and systems for managing technological process.

It is known that today microelectronics is one of the main factors of scientific and technological growth, which guarantees the economic development of society.

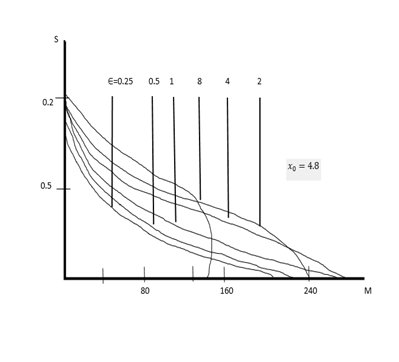

All existing technical developments in the textile and light industry, based on the introduction of modern microprocessors and other automation tools, are aimed at increasing labor productivity and improving product quality It should be noted that the equipment of units, machines and mechanisms that are part of the production system in the spinning mills with modern control means fully meets modern requirements. For this purpose, the AC motor is replaced by an asynchronous AC motor with a simple design, low cost, 1.5 to 2 times lower metal consumption (compared to an AC motor), a simple design, simple design, reliable operation and satisfactory performance. Asynchronous motors are widely used in various industries. The rotational speed of the induction motor is controlled by a simple, newly designed induction rheostat the torque is found as follows.

![]()

The thyristor-controlled device connects the asynchronous motor to the stator part, the mechanical characteristics of the phase rotor asynchronous motor are changed by changing the voltage, the induction rheostat resistance connected to the rotor part and the capacitor capacity.

To change the speed of rotation of the motor, the value of the magnetic flux generated in the magnetizing coil is changed, i.e. the magnetic flux is generated depending on the value of the current applied to this coil.

This is algebraically separated because the magnetic flux is opposite to the direction of the magnetic flux generated in the high-power coils. As a result, the active and inductive resistors of the induction rheostat change depending on the value of the reference magnetic flux. This change in turn leads to a change in the speed of rotation of the motor.

If the motor has a slip coefficient (S), the amount of energy consumed by the induction rheostat will be zero in the electrical parameters. This is done by changing the active inductive resistance of the induction rheostat by changing the value of the voltage applied to the stator windings while maintaining a certain amount of inductive rheostat resistance and by increasing or increasing the amount of capacitor.

In addition, the induction rheostat asynchronous motor is based on the number of revolutions of the electric drive rotor, which is automatically due to the change of the induction rheostat resistance. The result is a limitation of the rotor current and a change in the rotational speed of the electric motor. Adjusting the speed of the electric drive allows you to increase the efficiency of the grinding machine. Frequency control In asynchronous electric drive, the speed of rotation of the electric motor is adjusted by changing the frequency of the alternating current in the stator winding. The result is a control system that leads to energy savings.

The data obtained from the results of the scientific research show that it allows to reduce the frictional moment generated in electric motors and to start smoothly.

References

- Abramov A.G. Dimensional range of induction automatic rheostats for electric motors with a phase rotor. Electricity No. 12 the page 46-49, 1965.

- Basharin A.B., Novikov V.A., Sokolovsky G.G. Control of electrical drives L. 1982 Energy of the mountains.

- Shmelev A.N., Shishlo K. Electrical industrial enterprises of textile production Moscow Light industry 1975.

Количество просмотров публикации: Please wait